Research on Compatibility of Drug Packaging Materials

Home > Our Markets > Pharmaceutical Contract R&D Service > Research on Compatibility of Drug Packaging Materials

Compatibility study is a study means to ensure the safety and effectiveness of the selected packaging system for drugs, and provides a more scientific method and path for the selection of packaging for drugs. The compatibility service of medicine packaging materials from Titanium Pharmaceutical is based on the study of extractables of packaging materials. It can provide professional services in all aspects such as extraction study, simulation study, leaching study, adsorption study, safety assessment of compatibility study results and full life cycle management.

Study service on compatibility of disposable system (production process system)

Study service on compatibility of pharmaceutical packaging components and systems

Study service on compatibility of drug administration devices

Toxicological risk assessment and packaging material screening service

Special concern on substance testing service

It owns both CMA and CNAS qualifications, combines with the quality assurance system implemented by GMP requirements, and has passed multiple on-site inspections by the National Bureau and other institutions

It owns advanced laboratory equipment and a network version of the mass spectrometer workstation to ensure that the test results are accurate, reliable and traceable

It owns an experienced technical team, strictly follows CDE and ICH related guidelines to ensure compliance with implementation regulations

The report is under a lifelong responsibility system

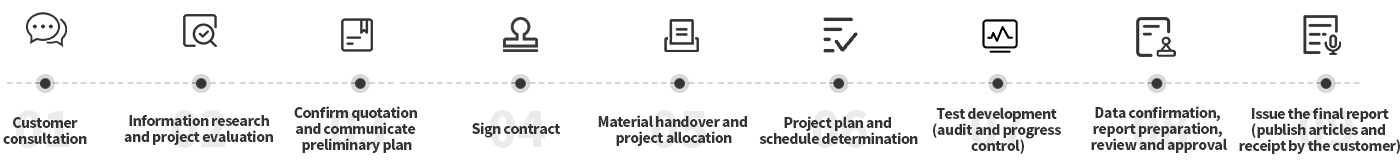

Customer consultation: consultation on compatibility of package materials

Information survey and project evaluation: The client prepares a compatibility information survey form, and evaluates the resource allocation (personnel arrangement, material preparation) required to complete the task on time according to customer needs and actual conditions

Confirm the quotation and communicate the preliminary plan: Design the preliminary test plan (including stability test) as required by the client, and confirm the quotation

Signing Contract

Material handover and project allocation: The client prepares the samples, standard products and their COA, MSDS required for the project, and delivers the samples, standard products and their COA, MSDS to the sample manager for sample collection and storage; the test unit assigns the project leader, QA and experimenter

Project plan and schedule determination: The project leader designs the plan and schedule plan according to project requirements, and submits them to the quality assurance department and the client for review and confirmation

Test development (inspection and progress control): the project leader will conduct formal tests after approving the project plan; the quality assurance department inspects the project process, and the project management department supervises the project progress

Data confirmation, report preparation, review and approval: The project leader reviews the nuclear test data, prepares the draft report, and submits it to the quality assurance department and the client for review

Issuing the final report (publish articles and receipt by the customer): The project leader signs and issues the final report, and the client ends the project. The original data and a final report will be archived by the company.